The edgings manufactured by Oly-Ola are generally referred to as plastic edgings. More specifically, our edgings are composed of medium density polyethylene (Poly) or MDPE and polyvinyl chloride (PVC).

Not all plastic edgings are created equal! What exactly are you selling/installing?

WITH OLY-OLA, IT IS STRAIGHT FORWARD AND SIMPLE:

Our PVC products are made of 100% recycled high quality PVC with carbon black concentrate and impact modifier added to strengthen the material and increase UV protection.Included in our PVC line: Oly-Ola's paver edgings, Teco-EdgTM and Super-EdgTM. High quality PVC is an excellent choice for these products due to its strength and rigidity.

Our Poly products are made of 100% recycled high quality MDPE with only carbon black concentrate added as a colorant and UV inhibitor.Included in our poly line: Oly-Ola's landscape edgings with the exception of Super-EdgTM. MDPE, is the perfect choice for lawn edgings due to its pliable nature. It is the perfect balance of strength and flexibility.

YEP, IT IS THAT SIMPLE!

With our plastic landscape edgings and paver edgings, there are no hidden additives or ingredients used to reduce cost and/or create the illusion of thickness or size. Not all other plastic edging manufacturers can say the same!

Oly-Ola is not the cheapest edging available and we never will be.

We offer a legitimate commercial grade edging in an industry where every low quality imitation claims to be the same. But don't worry, we are here to help you sort through the good, the bad and the ugly, and help you make the best choice for your landscape projects.

Avoid retail grade edgings and/or cheap imitations.

When your reputation is at stake, you want a product that is designed to last, especially if you are serious about what you are selling/installing. We’ve all seen plastic edging sticking out of the ground or broken around a landscape bed. Likely, a poorly constructed edging that has failed due to exposure to the elements and is now unsightly, giving all plastic edgings a bad reputation. When a high quality product is installed properly, it should be nearly invisible and last for decades. Avoid poorly constructed edgings by looking for the tell tale signs (see below).Avoid companies that use low cost additives.

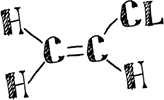

Some currently available edgings are manufactured with rubber bi-products and other cheap additives such as chalk, talc, silica or saw dust. Manufacturers will try to get away with this in order to reduce the amount of higher cost plastic used in their product. Other companies add chemical foaming agents (CFAs) to impart a cellular or hollow structure to their product. As CFAs are heated, bubbles are formed and dispersed throughout the plastic. Similarly, the CFAs reduce the amount of plastic required, thus reducing weight and cost. The more CFAs added, the more porous the plastic. The most common CFAs are hydrochlorofluorocarbons, methylene chloride, methyl chloroform, carbon dioxide, and nitrogen. Such low cost additives weaken the strength of the chemical bonds and the product is then more likely to break down when exposed to the elements. Of course, few manufacturers are going to admit that they are cheapening their product with such additives. You will likely have to look for the tell tale signs (see below).